♻️ Recycling solar panels

Where do we stand today and how to address the wave of PV waste incoming?

While generating electricity with solar panels doesn't emit CO2, the lifecycle of photovoltaic (PV) panels—from manufacturing to disposal— still has an environmental footprint. As solar is the fastest growing renewable energy, with a 25% compound annual growth (CAGR) in the USA alone, it’s crucial to address the lifecycle challenges of PV modules.

In this edition of Seagnal, a newsletter at the intersection of technology and sustainability, we dive into end-of-life (EoL) strategies for solar panels. We will first explore how we are dealing with solar panels now, the obstacles we face, and the opportunities that lie ahead.

Sizing the problem

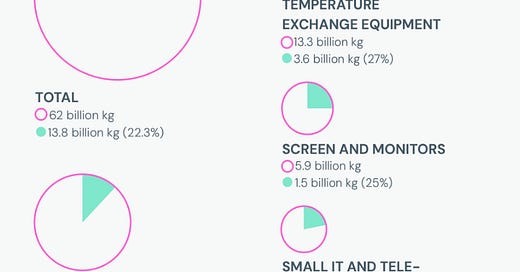

Photovoltaic panels accounted for only 1% of total electronic waste, or e-waste, in 2022. That’s a 1/10th of the waste from screens and monitors. However, this number is set to increase significantly as more panels reach the end of their 25 to 30 years lifespan. What seems manageable now is about to get bigger, much bigger.

Global e-Waste Monitor 2024, UNITAR.

PV panels have a long lifespan, typically around 25-30 years, with most manufacturers guaranteeing 80% performance after 20 years (some newer models even guarantee 87.4% performance after 30 years!). Given the significant increase in solar installations over the last decade, we can expect a surge in PV e-waste around the 2050s.

Electricity generation by technology, with speed to reach 1000 TWh Source: Ember.

With a quick back-of-the-envelope calculation, we estimate that annual PV waste could reach around 20 billion kg by 2050 — or about 2 kg per person — representing a 30-fold increase over today's levels.

(In 2023 we installed >400 GW of PV panels, at about 20kg/400W per panel = 0.05 kg/W *400 GW = 20 Billion kg. Assuming most of the 2023 panels will be discarded or upgraded by 2050, plus some from weather events and malfunction we get 20 Billion kg of PV waste)

While 2050 may seem distant, it’s a problem we need to address now. There's already some non-negligible PV waste today, and we must prepare for the incoming wave.

Amidst the hopeful embrace of solar panels and electronic equipment to combat the climate crisis and drive digital progress, the surge in e-waste requires urgent attention. Nikhil Seth, Executive Director, UNITAR

PV recycling: challenges and opportunities

Now that we have a clear understanding of the scale of the problem—and the opportunity—let’s delve into the current state of PV recycling.

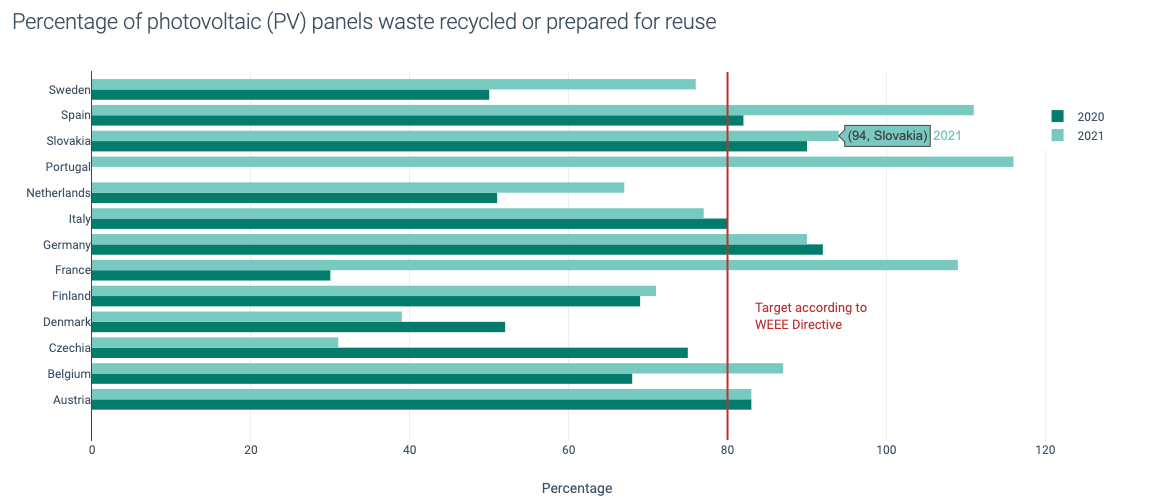

In their 2021 report on PV recycling, the National Laboratory of the U.S. Department of Energy (NREL) reported that: “anecdotal evidence suggests that most early retired and EoL PV modules are landfilled or otherwise disposed of resulting in less than 10% of modules being recycled in the United States”. They highlight a stark contrast with European countries, which have “nationwide policies that mandate PV module recycling”, resulting in recycling rates above 50%.

Recycling materials from green energy technologies - European Environment Agency. A rate above 100% occurs if stored PV waste from previous years is recycled in the reporting year.

Recycling presents the opportunity to recover rare metals used in PV panels. For example, the demand for silver just for manufacturing solar panels is forecasted to rise to about one-fifth of total silver demand by 2030. Yet, most current PV module recycling efforts, including in Europe, focus on the aluminum frame and the glass cover, with parts of the PV panels containing silver, copper, and silicon incinerated.

Furthermore, the technical challenge of recycling precious metals is becoming increasingly difficult with each new PV generation. As we manufacture more performant, cheaper and complex modules, they get harder and less economically viable to recycle (for example using less silver). This underscores the need to also consider end-of-life (EoL) strategies at the manufacturing stage. The NREL emphasizes this point:

[…] to provide PV module labels with concentrations of hazardous material (such as lead) could enable information exchange between stakeholders and eliminate the need for expensive and variable hazardous waste characteristic testing - Solar Photovoltaic Module Recycling: A Survey of U.S. Policies and Initiatives, NREL

Furthermore, recycling PV panels can reduce reliance on external supply chains, a crucial consideration as discussed in Manufacturing Wars. By reclaiming valuable materials from discarded panels, we can mitigate geopolitical risks, reduce carbon emissions from transportation and create local jobs.

To recap, PV waste could represent a third or more of our total e-waste by the 2050’s. Current recycling rates are still low in some parts of the world but can be improved with policies that mandate recycling and specify recovery targets for valuable metals. Furthermore, policies and EoL strategies must also be addressed at the manufacturing stage, to capture the full benefits of recycling PV modules.

Thinking outside the box

In the waste management hierarchy: "reduce, reuse, recycle", recycling is the last resort. Instead of recycling solar panels, couldn’t we reuse them?

Even after long lifespans, properly maintained solar panels can still operate with decent performance. Repurposing these panels presents logistical and technical challenges, but it can effectively give them a second life.

This second life could also expand the addressable market of clean energy by giving underserved communities or developing countries the means to reduce their carbon emissions and increase energy security for a fraction of the cost. Recognizing that material costs often account for only a third of installation expenses, this would require innovation in installation services, as well as handling the eventual end-of-life of these panels properly.

Other avenues to explore for reducing the environmental footprint of solar energy include leveraging new technologies such as thin-film solar panels that use less material from the outset. Additionally, repurposing other types of PV-related waste, such as roof racks for residential installations and concrete or metal foundations for solar farms, can further the environmental footprint of solar energy.

In other words, while recycling is necessary for damaged and very old panels, many still-functional panels could be repurposed instead. This approach could introduce a service-based business model to the EoL phase of panels, offering cheaper clean power for households that can’t afford new systems, either in the same country or abroad.

Summing it up

As solar energy continues to grow rapidly, addressing the environmental impact of photovoltaic (PV) panels becomes increasingly critical. The naturally long lifespans of PV modules mean we will face a wave of PV e-waste by the 2050’s. Because of the scale of the issue, we need to prepare effective end-of-life strategies now, while scaling up and improving current PV industrial recycling processes.

With anecdotal evidence that less than 10% of PV modules were being recycled in 2021 in the U.S., it seems we could be more prepared. Implementing policies that mandate recycling and specify recovery targets for valuable metals seems to be a necessary starting point to provide the sector with the certainty needed for businesses to innovate and attract funding. We should also explore addressing EoL strategies at the manufacturing stage, repurposing solar panels for a second life, and continuing to innovate with new technologies such as thin-film solar.

Ultimately, the challenge of managing PV waste offers opportunities to recover valuable materials and reduce the lifecycle footprint of PV modules. Adopting a circular economy approach can also extend the lifespan of functional panels through reuse, potentially benefiting underserved communities and reducing overall environmental impact, by giving solar panels a second and maybe third life!

From Geneva 🇨🇭,

Jean

PS: Got tips to improve the newsletter or topics you would like me to explore? Reply to this email with your suggestions!